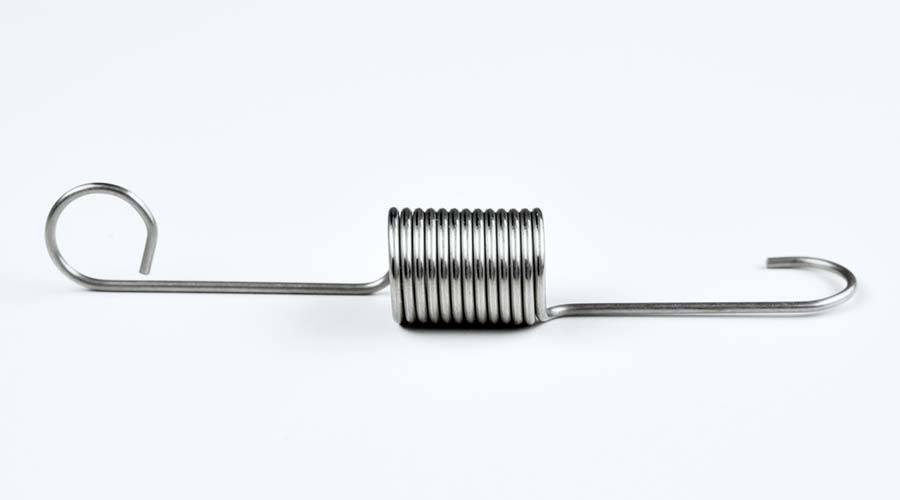

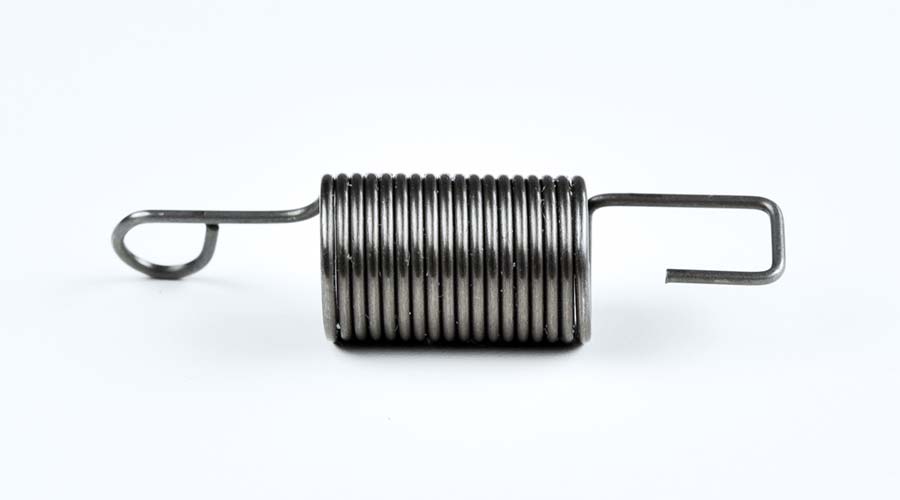

Tension springs absorb energy when they are pulled apart, which is discharged when the tension is released.

Tension springs are produced with a wire diameter from 0.2 – 4.0 mm. From sample springs and individual springs in a pilot series to serial production with several million units per spring and year, we offer a wide range of different springs in our portfolio.

We are pleased to produce special solutions for our customers. These tension springs are specially adapted to the requirements of our customers.